Contact phone number

+8613905342326

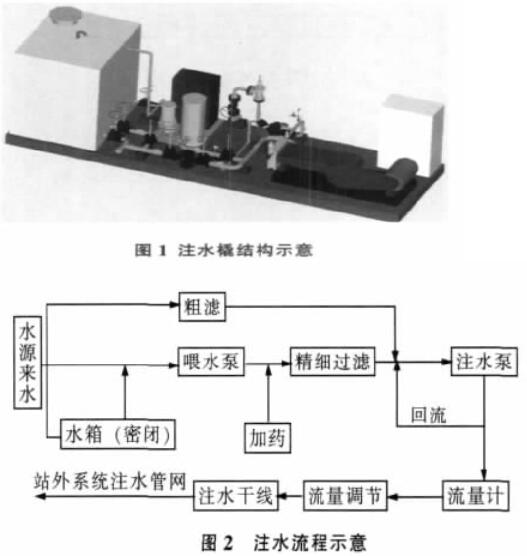

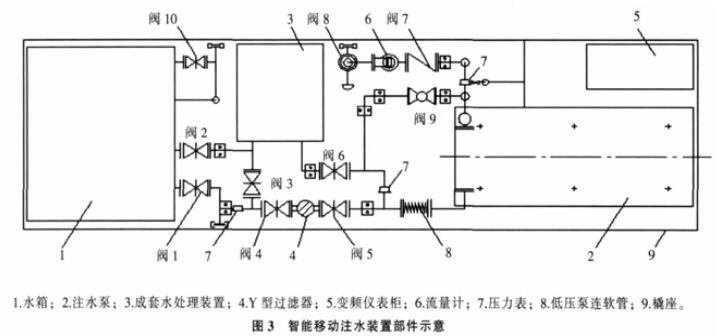

Case One& Nbsp& Nbsp; Small intelligent mobile water injection device

&Nbsp& Nbsp; Device Description

Location: Yanchang Oilfield

The device mainly consists of a water tank, an injection pump, a complete water treatment device, a control systemvalveComposed of pipelines, measuring instruments, and pry seats, with integrated design for water source, filtration, dosing, boosting, metering, and refluxequipmentThe valves and process pipelines are centrally installed on a pry seat. Used for water injection in single or multiple wells with a daily water injection volume of less than 300m3.

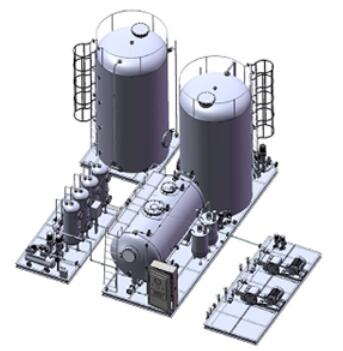

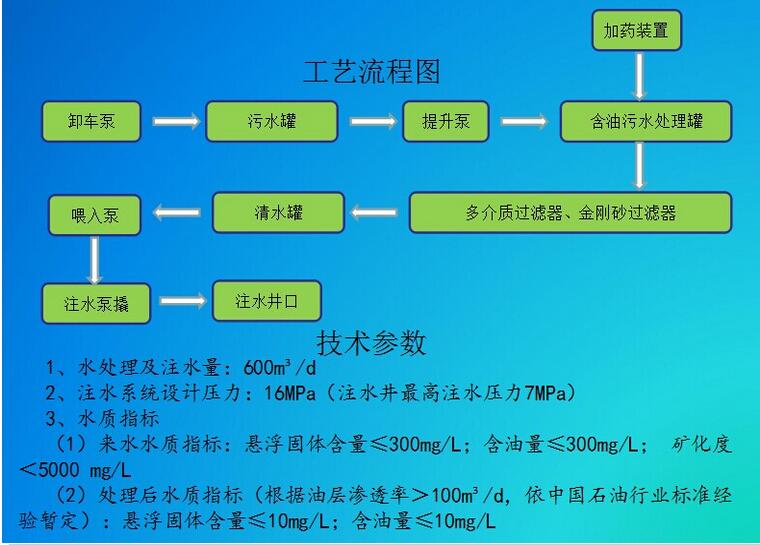

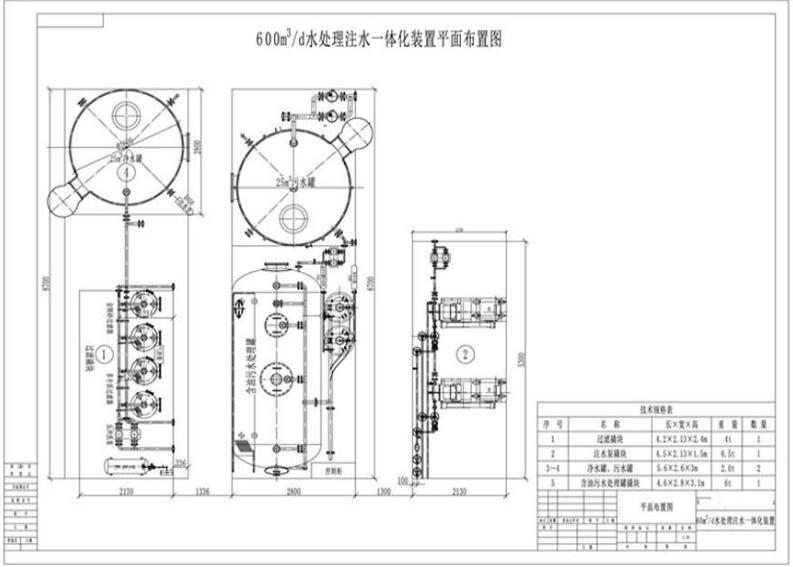

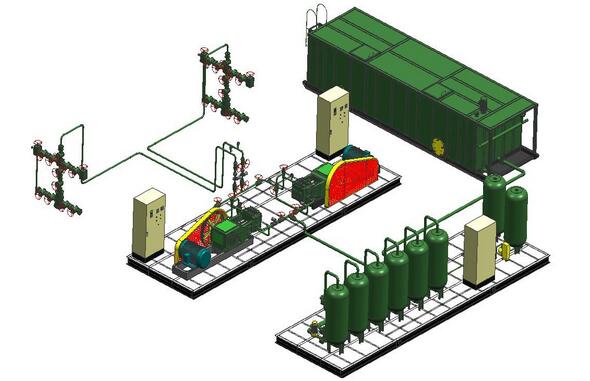

Case 2& Nbsp& Nbsp; Project Description of 600m3/d Integrated Water Treatment and Injection Device

Location: Changqing Oilfield

Main components:

Sewage tank pry block& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp; (1 seat)

Oil containing wastewater treatment tank pry block (1 unit)

Filter leverBlock& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp; (1 seat)

Water purification tank pry block& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp; (1 set) Water injection pump pry block& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp& Nbsp; (1 seat)

&Nbsp;

Case Three& Nbsp; Mobile pry mounted water injection equipment

(Shengli Oilfield)

Main components:

Sewage tank pry block; (1 seat)

Filter pry block& Nbsp& Nbsp& Nbsp; (1 seat)

Water injection pump pry block; (1 seat)

&Nbsp;

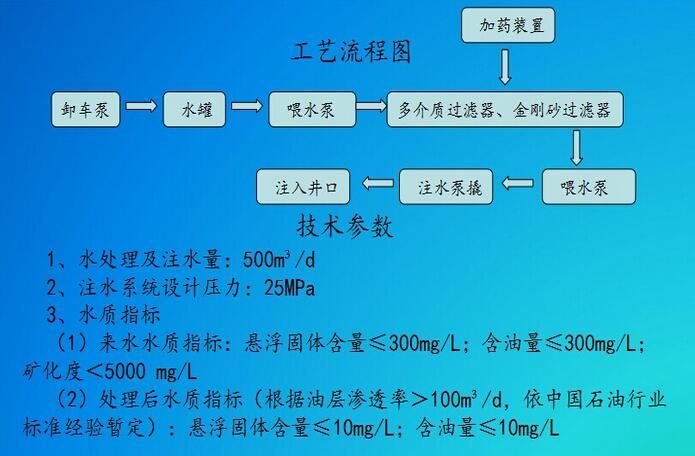

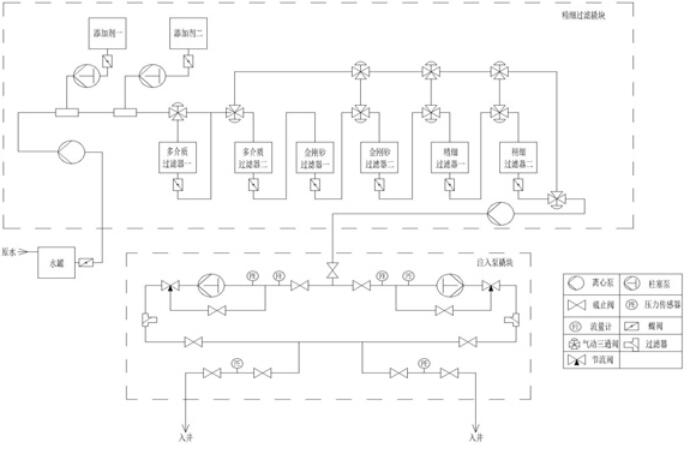

Based on the incoming water quality and injection requirements, select the filter process for water flow to enter by controlling the three-way valve on the pipeline. There are two sets of additive adding devices designed before the raw water enters the filter, equipped with metering pumps, which can accurately add water treatment agents according to the water injection process. The raw water is treated through a filter to meet the injection requirements, and then enters the injection pump block through the feed pump. There are two sets of injection processes symmetrically arranged inside the injection pump pry block, and the opening valves can be adjusted according to the needs for one or two pump injection operations. The process is equipped with a flow meter and pressure sensor to monitor the pump injection pressure and flow rate in real time. And adjust it through the shut-off valve. The pump outlet is equipped with a throttle valve and a reflux manifold to control the stability of the pump injection and expand the range of flow conditions.

&Nbsp;

On site backup for Shengli Oilfield Island Oil Production Plant

On site use of Linpan Oil Production Plant in Shengli Oilfield